Our products

OUR OFFERS

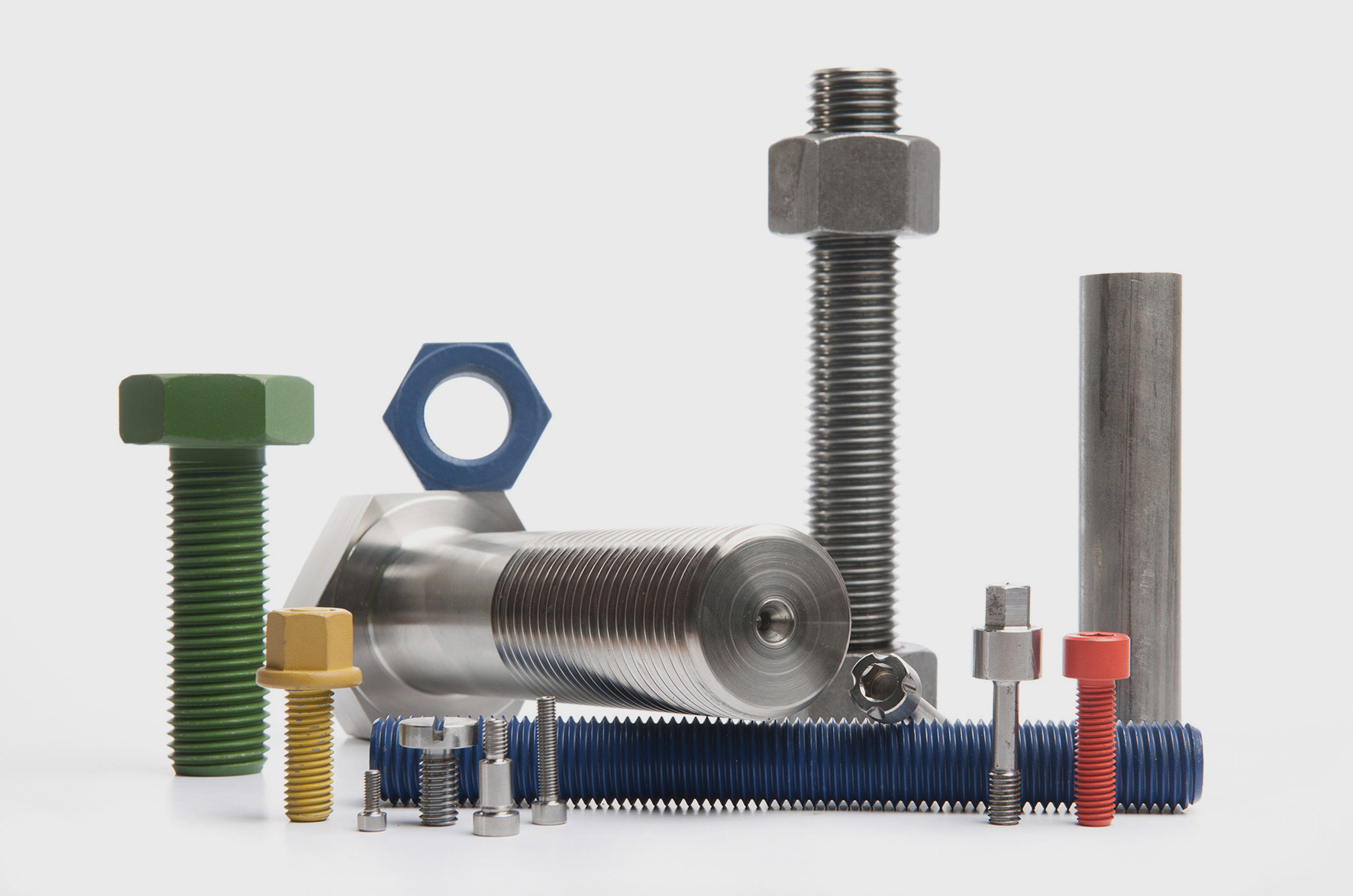

FOR 43 YEARS, ZOBEL HAS BEEN MANUFACTURING NUTS AND BOLTS FOR INDUSTRY…

Our company manufactures, stores and delivers both standard and custom-made bolting parts.

We can also deliver parts made by our partners at any time.

THE FOUR SPECIFICATIONS OF OUR PARTS

Size, material, surface finishing, documentation and testing

At Zobel, we deliver 30,000 lines and 70,000 products every year. Around a hundred new products are added to our database every day.

Our production capacity is so powerful and our products can be used in so many potential ways that it would be impossible to create a comprehensive inventory of Zobel offers.

That is why we use four main specifications to define each product:

SIZE

| Studbolt | Double end studbolts |

| Nuts | Rods |

| Bolts | Plug |

| Screws | Stirrup |

| Washers | Parts according to drawing or standard |

The sizes of our products comply with international standards (DIN, NFEN, ANSI, ISO, etc.) or with specifications provided by customers.

From a part weighing a few grams to a unit weighing dozens of kilograms, from an M4 to an M120 diameter, from a 5/16″ to a 6″ diameter, Zobel will meet your needs regardless of the part’s size requirements.

MATERIALS

Zobel takes meticulous care in choosing its materials and offers a very wide, and above all very qualitative, range.

One of Zobel’s strengths lies in its technical expertise in raw materials.

Carbon steel, stainless steel, duplex, super duplex, aluminium bronze, refractory metal, nickel-based alloys, titanium… Every day, we handle almost 300 materials according to ASTM, DIN and ISO standards.

The main materials used by Zobel (non-exhaustive list):

| CARBON STEEL | STAINLESS STEEL | DUPLEX & SUPER DUPLEX | OTHERS |

|---|---|---|---|

| 21CrMoV5-7 | ASTM A193 B8 CL1 & CL2 | ASTM A453 GR660 A | 6082 T6 |

| 25CrMo4 | ASTM A193 B8M CL1 & CL2 | ASTM A453 GR660 B | ALU 5754 (AG3) |

| 42CrMo | ASTM A193 B8T CL1 & CL2 | ASTM A453 GR660 C | ALU 7075 (AZ5GU) |

| ASTM A193 B7 | ASTM A194 GR 8 | ASTM A453 GR660 D | ALU P40 |

| ASTM A193 B7M | ASTM A194 GR 8M | ASTM A479 S 21800 | ALU P60 |

| ASTM A194 GR 2H | ASTM A194 GR 8MA | ASTM A479 S 30815 A | ASTM B348 TITANE GR2 |

| ASTM A194 GR 2HM | ASTM A240 321H | ASTM A479 S 31254 | ASTM B348 TITANE GR23 |

| ASTM A194 GR 7 | ASTM A320 B8C | ASTM A479 S 31803 | ASTM B348 TITANE GR5 |

| ASTM A194 GR 7L | ASTM A320 B8CA | ASTM A479 S 32550 A | ASTM B348 TITANE GR7 |

| ASTM A194 GR 7M | ASTM A320 B8MA | ASTM A479 S 32760 | CuAl10Ni5Fe4 |

| ASTM A194 GR 7ML | ASTM A479 304L | CuAl11Ni5Fe5 | |

| ASTM A320 L43 | ASTM A479 316L | CuAl9Ni3Fe2 | |

| ASTM A320 L7 | ASTM A564 GR630 | CuAl9Ni5Fe4 | |

| ASTM A540 B24 CL3 | INOX A2 | CuAl9Ni5Fe4 | |

| ASTM F436 | INOX A4 | CuBe2 | |

| ISO 898-1 CL10.9 | X12Cr13 | CuSn7Zn4pb7 | |

| ISO 898-1 CL12.9 | X19CrMoNbVN11-1 | ||

| ISO 898-1 CL8.8 | X22CrMoV12-1 |

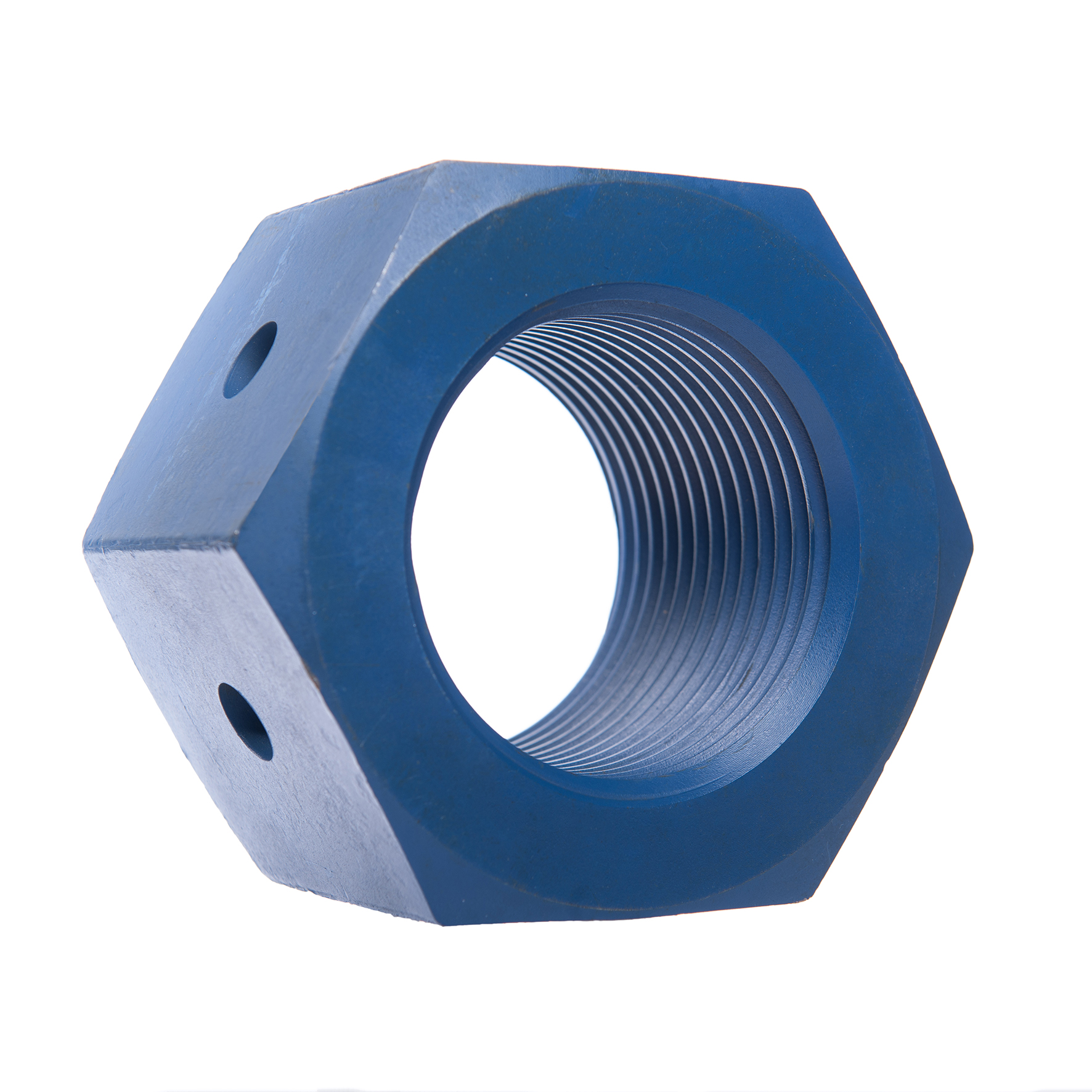

SURFACE FINISHING

In the industrial, chemical and energy sectors, parts are always used under highly specific or even extreme conditions. It is often necessary to add a coating to these parts to improve their physical properties.

At Zobel, we have mastered many types of surface finishes designed to make bolts, screws and fasteners more resistant to corrosion, to improve their physical appearance and to make assembly easier.

Our ergonomic and flexible supply chain means that costs are easier to control and surface finishes are quicker to apply.

| Electrolytic Coating | Lamellar Coating | Galvanised Coating |

|---|---|---|

| Zinc-plated ROHS Zinc plated Degassed Bichromate zinc-plated Zinc Nickel | Deltaprotekt ® Zintek ® Magni Coating ® Géomet 500 ® Dacromet 500 ® | Hot |

| Fluoropolymer | Phosphatation | Others |

| Xylan 1070 & 1424 Xylar + Xylan 1070 & 1424 Zinc nickel + xylan 1070 & 1424 | Manganese Zinc Oiled zinc | Amercoat Galvanic browning Pickling Passivation Stanal® Gerardization |

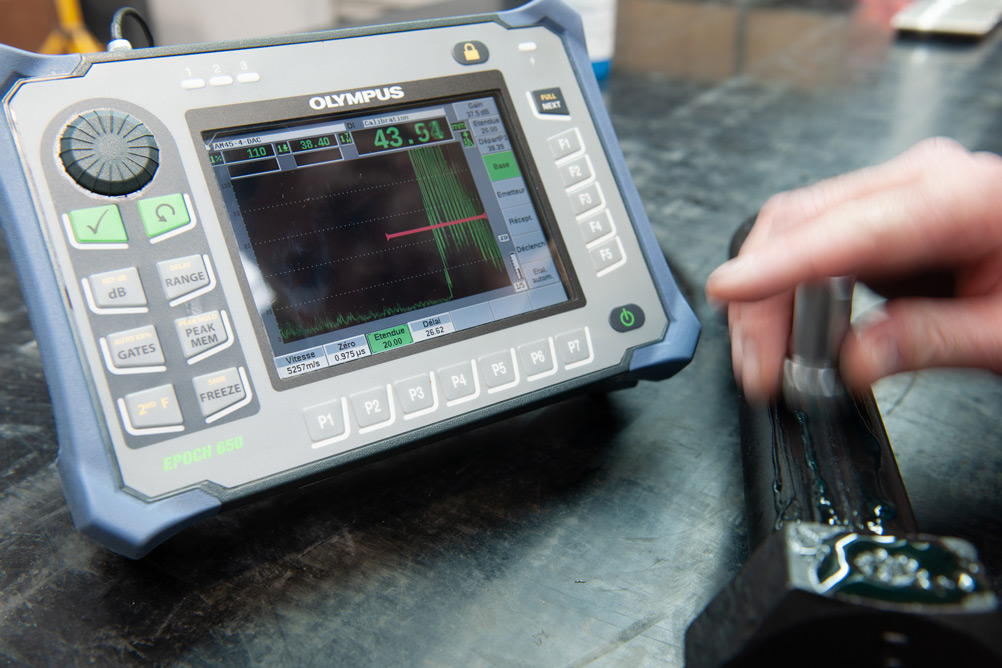

DOCUMENTATION AND TESTING

Every project is unique and every part must be flawless.

That is why, at Zobel, we take documentation and testing extremely seriously.

Do you need certificates, additional testing or quality-related documents? Zobel will be with you every step of the way and make every effort to meet all your needs when it comes to technical documentation and quality control.